【Board Level Reliability】

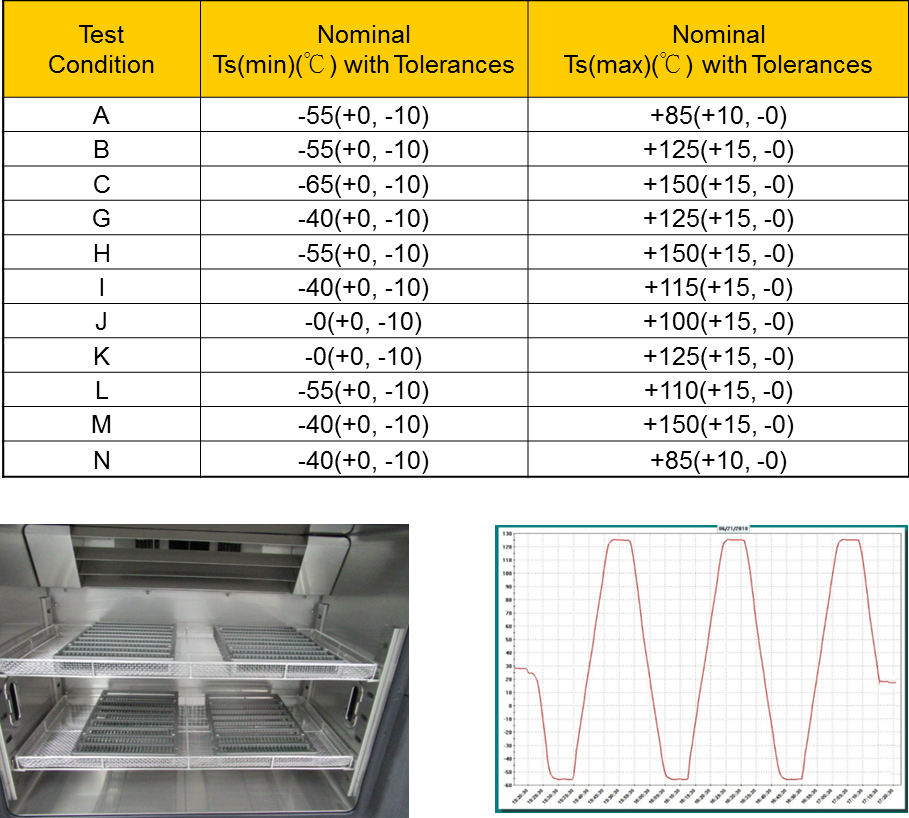

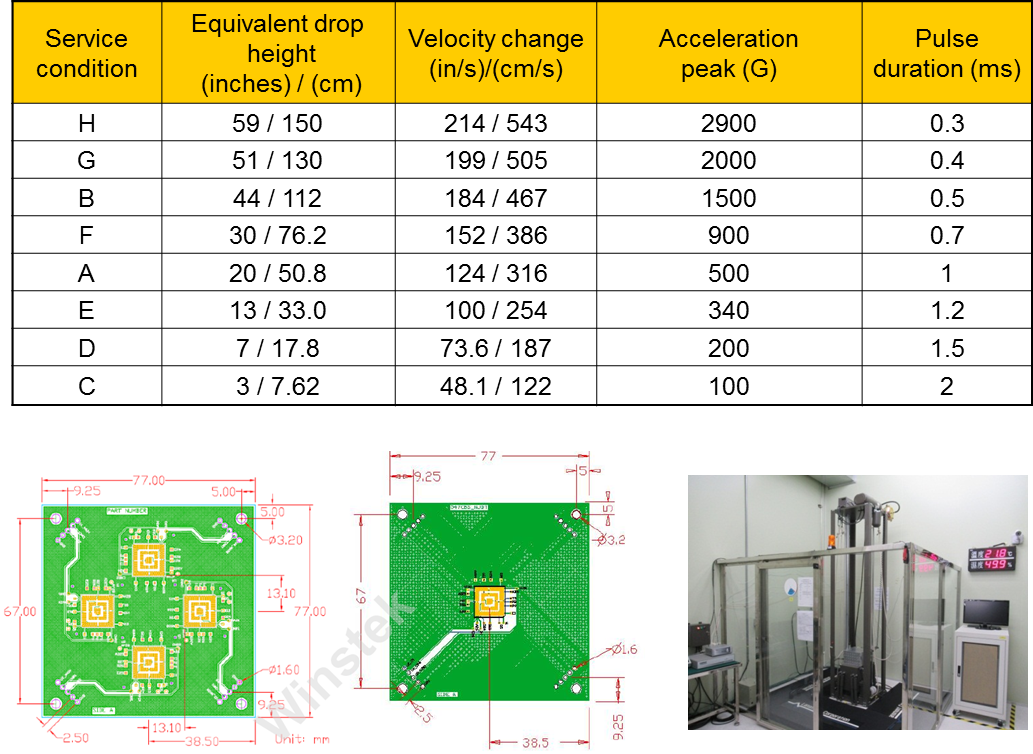

Mechanical ShockEvaluating the IC package, during the process, packaging, transportation and normal use, the solder joint position (Solder Joint) will cause deformation and damage to the service life due to the dynamic deformation of the board. Test condition

Reference SpecificationJESD 22-B104 |

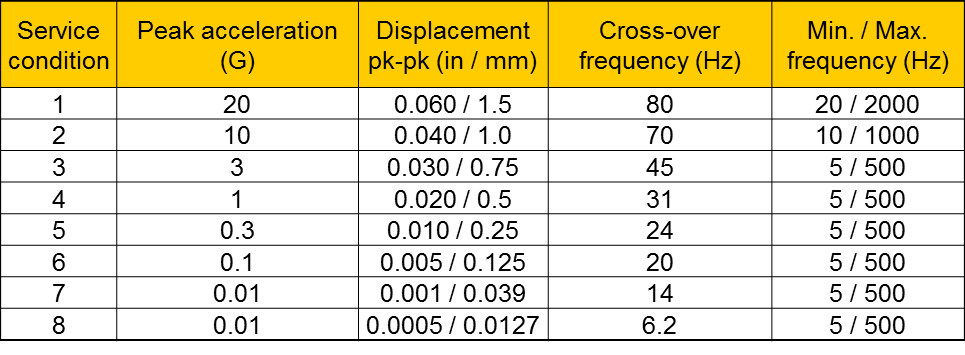

Vibration TestWhen the product is subjected to the vibration stress effect, the vibration reaches the repeated stress and causes fatigue, which is easy to cause the board level of the solder joint to break. At the same time, the component is subjected to vibration to generate a resonance response due to the natural frequency response of the assembly method or mechanism design (Resonance Amplification). The phenomenon is more damaging to the structure. |

|

Test condition

Reference SpecificationJESD 22-B103 |