【SMT Service】

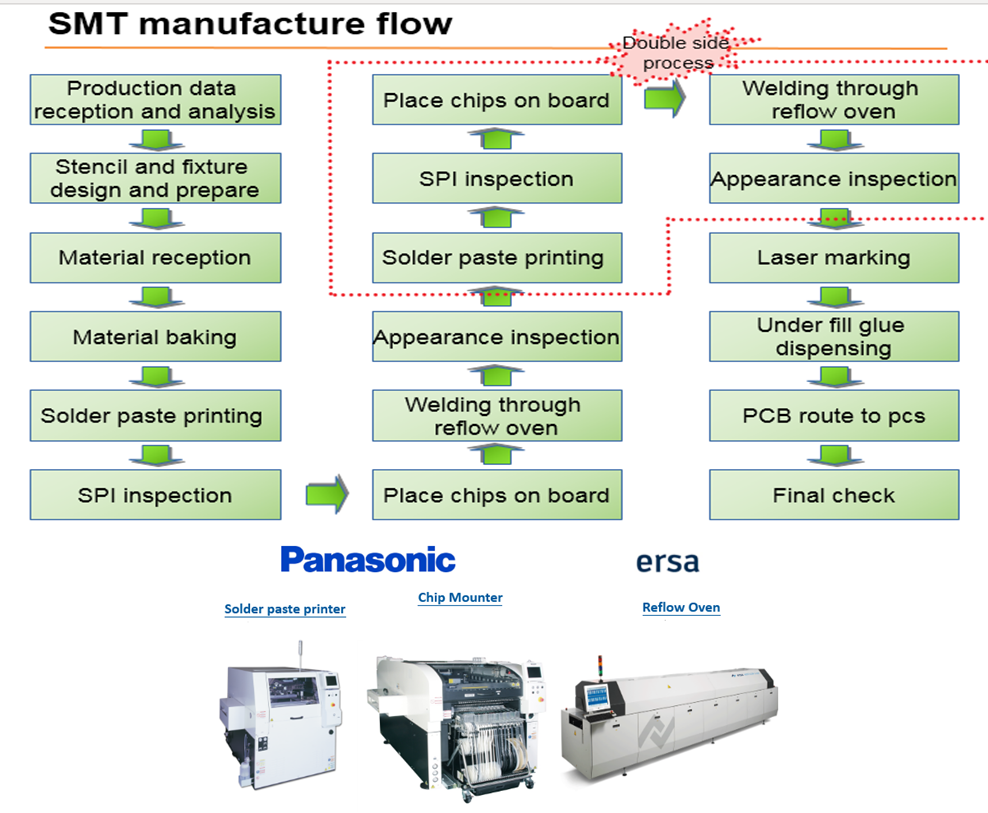

Surface Mount TechnologyThe SMT process is the primary key site for the board reliability test (BLR). The quality of the IC adhesion on the PCB directly affects the correctness of the product test results. Key quality factors include solder paste, printing parameter settings (such as mold release spacing and time, printing speed), placement accuracy, and steel plate design. To provide timely service and stable product quality, Winstek has set up a SMT line for our customer. The SMT line includes solder paste printing machine, solder paste inspection machine (SPI), Mounter, reflow furnace, and high-magnification optical microscope. The ambient control of the reflow furnace provides better quality of the soldering. The amount of solder paste and the Cpk of solder paste printing quality are automatically checked, respectively. For wafer level chip scale package (WLCSP) process, underfill is also provided. To meeting the scaling of the component, the Mounter is capable to handle the pin pitch as small as 0.20 mm.

|